ResourcesFAQ/Downloads

Building Security Systems

Building security is the protection of property, assets, and occupants from intruders, perpetrators of violence, and unsafe or hazardous situations that can cause them harm or damage. Its goal is to deter, prevent, detect, and respond to physical security violations effectively.

Fire and safety systems

Fire and safety systems are designed to detect the outbreak of fires and provide warnings, for example by sounding alarm bells throughout the building. Integrating fire protection and fire alarm systems with building automation systemscan offer efficient and cost-effective operation.

Wireless Environmental Sensors

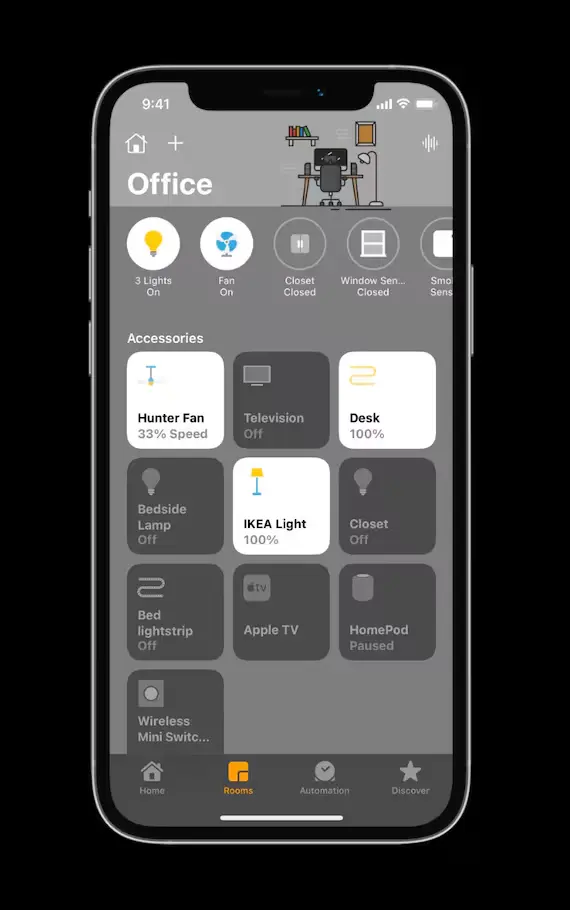

Wireless environmental sensors in building automation can monitor environmental conditions in a building, such as temperature, humidity, occupancy, and light levels. It communicates wirelessly with a central control system, which collects and analyzes the data and makes decisions to optimize building performance.

Industry 4.0

Industry 4.0, in the latest version of Internet of Things which encompasses IIoT and smart manufacturing, marries physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better-connected ecosystem for companies that focus on manufacturing and supply chain management.

Whitepapers

Our whitepapers describes best practices for creating scalable and secure building automation for maximum efficiency

Whitepapers

Our whitepapers describes best practices for creating scalable and secure building automation for maximum efficiency

Whitepapers

Our whitepapers describes best practices for creating scalable and secure building automation for maximum efficiency

Whitepapers

Our whitepapers describes best practices for creating scalable and secure building automation for maximum efficiency

General Questions Regarding Building Automation

There are several different types of building automation systems available on the market today. These include intelligent systems that use sensors to detect occupancy and make adjustments to heating, cooling, and lighting levels; programmable logic controllers (PLCs) which are used to control different functions of a building or system; open protocol systems that allow for communication between various types of equipment; and remote access systems that allow users to manage the BAS from any location.

General Questions Regarding Industrial Automation

The four main types are fixed, programmable, flexible, and integrated automation. Fixed automation is often used in high-volume production settings, while programmable automation is better for lower volume production runs. Flexible automation offers more process flexibility and automated changeovers.

Automation systems include sensors, transmitters, control systems, output devices, and actuators.

Sensors can sense temperature, pressure, flow, and level. Control systems can include PLCs, DCSs, and PID controllers. Output devices and actuators can include drives and control valves.

Communication protocols enable industrial communication so managers can have greater visibility and control of their operations. With connected PLCs, machine controls, HMIs, sensors, and systems, manufacturers can overcome data siloes and drive industrial automation. The industry as a whole has begun to move to industrial ethernet communication protocols. There are now many, many communications protocols available, depending on various factors including equipment and devices in use, networks, and the goal of the control system.

Industrial automation uses automated control devices to replace manual labor and dangerous assembly operations. There are three types of controllers used in industrial automation: Programmable Logic Controllers(PLCs), Distributed Control System(DCSs), and Programmable Automation Controller (PACs).

Client Testimonials

Top Industry RatedAutomation Experts

Mashtek Automation offers smart automation solutions for industries, offices, hospitals, etc in India and across the globe to make every building, industry or process smart and secure!

Apollo Tyres

"We turned to Mashtek for their top-notch industrial automation solutions. Their robotics team revolutionized our production process, making us more competitive than ever. Thanks, Mashtek!"

MRF Tyres

"Mashtek's quality assurance and testing services have been instrumental in maintaining our product standards. Their attention to detail is unparalleled, ensuring our products meet regulations."

Wonderla

"Whether it is in the upfront engineering and design stage of a project, or in the execution or maintenance stages, Mashtek has always provided a great level of support in running processes efficiently."

ISRO

"Got really good support for Paint Shop and Conveyors Synchronization as well as HMI material supply and Program migration. We are looking forward to collaborating with Mashtek in the future."

Mahindra

"Mashtek has been our trusted partner for years. Their manufacturing consulting services helped us streamline our operations and boost productivity. They are the go-to experts in the industry!"